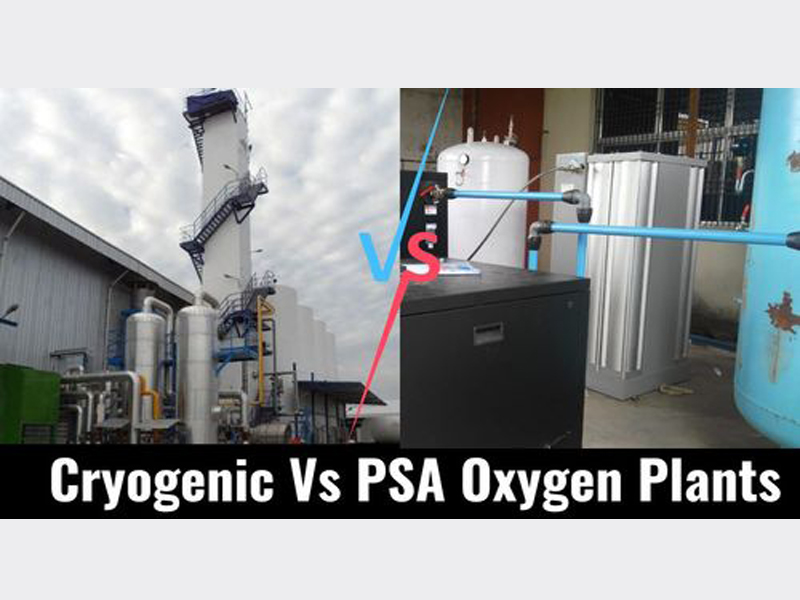

Hospitals, Healthcare centers, and clinics use various ways in order to generate medical oxygen. Some of the most important ways of doing that is through Cryogenic plants, Liquid oxygen generating system, and PSA Oxygen generator system. All these systems are very different from each other. The way of producing medical oxygen in both systems is very different.

Customers who are new to the oxygen sector are unable to distinguish between PSA and cryogenic-based oxygen plants. Most of the time, they have the incorrect belief that all O2/N2 gas plants are priced similarly to PSA plants. Costs for cryogenic and pressure swing adsorption facilities are not comparable, because their respective technologies are entirely different.

So, do not worry we are here for you to tell you the main difference between Cryogenic plants and PSA plants.

Definition Explained: Cryogenic Vs PSA Oxygen Plants

PSA Systems: Using PSA systems, medical oxygen can be produced on-site at any hospital, clinic, or healthcare facility. Air is a key component in the PSA systems' oxygen generating process. The oxygen content of air is 20.95 percent and nitrogen is the other significant gas (78.09 percent ). In a PSA process, the air is pushed through an adsorbent bed under pressure. Because gases have a propensity to be adsorbed by solids in such circumstances, PSA techniques rely on this phenomenon. In the PSA-based oxygen synthesis process, nitrogen is attracted to the adsorbent more potently than oxygen.

Cryogenic Oxygen Plants: A commercial facility that produces molecular oxygen with comparatively high purity is known as a cryogenic oxygen plant. The second-largest industrial gas and the element with the highest frequency in the crust of the earth is oxygen.

Purity Of Oxygen: Cryogenic Vs PSA Oxygen Plants

Compared to cryogenic air separation, which is used to produce oxygen with the highest purity and largest volume, PSA is best for producing oxygen with lower purity and volume.

In contrast to PSA plants, cryogenic plants can create oxygen on a massive scale and with extremely high purity. PSA plants with a configuration of 200 m3/hr, let alone tonnage plants, are hardly accessible.

Generation Of Nitrogen

Both liquid and gaseous oxygen can be produced using the cryogenic technique. Oxygen can be produced at a cryogenic oxygen plant in both liquid and gaseous forms. Additionally, the PSA oxygen generating plant can only generate either gaseous oxygen or nitrogen.

Only one product gas, either nitrogen or oxygen, can be produced by the PSA plant. A cryogenic plant, on the other hand, can create both oxygen and nitrogen. Your oxygen plant can also produce nitrogen if you have one. You would have to purchase a nitrogen cylinder filling device though.

Pricing: Cryogenic Vs PSA Oxygen Plants

Because PSA pressure swing adsorption uses less complex technology, it is less expensive to manufacture PSA plants than cryogenic-based ones. Cryogenic technology is advanced and necessitates the employment of complex procedures and components that are far more expensive than those used in the PSA process.

Lifespan: Cryogenic Vs PSA Oxygen Plants

Cryogenic and PSA plants both have unique life cycles. Cryogenic plants have life cycles of over 25 years, whereas PSA is known to have one of over 10 years. The cryogenic O2/N2 plants' use of cryogenic grade stainless steel, which can resist extremely high temperatures and pressure, makes this possible. Using TIG argon welding, cryogenic air separation devices are joined.

Why PSA Over Cryogenic Plants?

- The PSA technology's (pressure swing adsorption) method is a very clean one. The sole "raw material" is air.

- This implies that you have the freedom to manufacture oxygen whenever you want, wherever you want, and in whatever quantity and quality, you want. No more awaiting supplies from outside vendors or overpaying for your O2.

- It is less expensive to produce O2 using the PSA method. For your application, it provides the greatest industrial oxygen pricing.

- To give you a constant flow of oxygen, the PSA procedure is repeatedly performed.

Why Cryogenic Over PSA Plants?

- Cryogenic air separation produces oxygen with a high purity level of over 99.5%.

- The resulting high purity product can be kept in cylinders or stored as a liquid.

- These cylinders can also be sold to customers in the medical industry, for use in welding, or as diving breathing gas when combined with other gases.