The pressure swing adsorption (PSA) approach, which uses outside air as a staple, is the foundation of the oxygen generator. The ambient air features a 21 percent oxygen content, a 78 percent nitrogen content, a 0.9 percent argon content, and a 0.1 percent rare gas concentration. The PSA technique produces oxygen-enriched air with a level of a minimum of 93 percent by statically separating the gases within the air by employing a molecular sieve built to adsorb nitrogen struggling.

The oxygen generator is created of a pneumatic system (valves, filters, pressure regulator...), an oxygen tank, two separation vessels with molecular sieve adsorbers (zeolites), and an automatic device.

Every day, hospitals on five continents receive life-saving oxygen from medical PSA oxygen generators. Whether the nation's standards are set at 99 percent, 95 percent, or 90 percent, the oxygen generator will satisfy your needs. From tiny rural clinics to major urban hospitals, PSA oxygen generation systems can give a secure, cost-effective replacement for the delivery of frozen oxygen.

Pressure swing adsorption is the method by which ambient air passes through an inside filtering system with a sufficient total extent to get rid of nitrogen (N2) from the air while concentrating the remaining oxygen (O2) to a selected purity (PSA). Usually included are a compressor, dryer, filters, twin separation chambers, a reservoir, and controls.

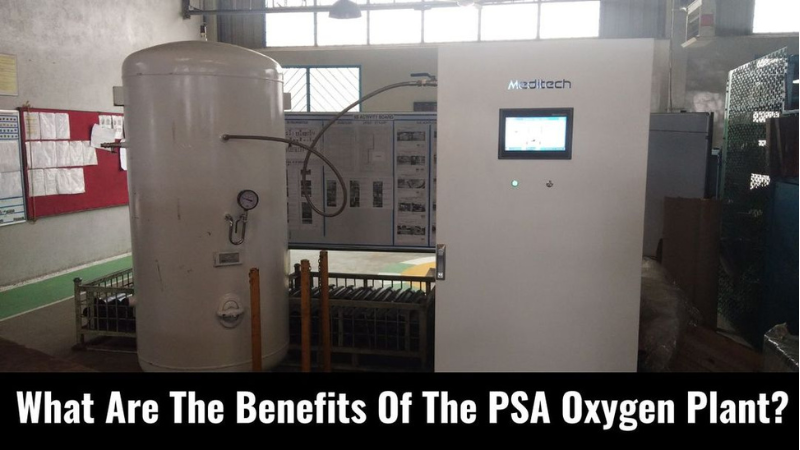

What Are The Benefits Of The PSA Oxygen Plant?

The PSA technology's (pressure swing adsorption) method may be a very clean one.

This implies that you simply have the liberty to manufacture oxygen whenever you wish, wherever you wish, and in whatever quantity and quality you wish. No more awaiting supplies from outside vendors or overpaying for your O2. it's less costly to supply O2 using the PSA method. For your application, it provides the best industrial oxygen pricing.

Using a molecular sieve created to adsorb nitrogen harassed, the PSA process involves the static separation of air gases, producing oxygen-enriched air with a level of a minimum of 93 percent oxygen.

The oxygen generator consists of two separation jars with molecular sieve adsorbers (zeolites), one complete pneumatic system (valves, filters, pressure regulator, etc.), and one oxygen tank.

The most important advantage of PSA oxygen generators is that only medical-grade oxygen of the best quality should lean to patients; it's a critical medication that's required at the least levels of the healthcare system. Pressure swing adsorption (PSA) oxygen-producing plants create medical-grade oxygen. The technical requirements that a PSA Oxygen Plant must meet to deliver medical-grade oxygen are described in this publication.

Medical oxygen plants are constructed and employed in a large number of hospitals in India. medical aid units, physical therapy clinics, and other medical facilities receive medical oxygen from a medical oxygen plant (Operation Theaters). it's frequently used during anesthesia as another inhalation anesthesia to cut back the quantity of oxygen ingested. Medical oxygen is currently delivered employing a cylinder manifold. the benefits of a medical oxygen generator that includes an on-site medical oxygen gas generator moreover as a cylinder backup are already being reaped by savvy hospitals.

Hospitals everywhere on the planet are finding reliable and affordable alternatives to medical oxygen generators. Their patients' oxygen needs are satisfied by an on-site oxygen plant. It lowers the prices related to ordering, receiving, and keeping track of oxygen supplies at your hospital. Accidents involving manual handling, costs associated with replacing cylinders, and regular cylinder refilling are all costly. Liquefied petroleum gas is also prohibitively expensive if the oxygen supply can only be obtained in a very remote location. If the operator isn't taking note, hospitals can run out of medical oxygen cylinders.

MUST-READ ||

When Is An Oxygen Cylinder Considered Empty?Oxygen generators are often used for a range of purposes, like aerating wastewater, accelerating biological treatment, raising productivity in gold mines, and promoting the expansion of hatchery trout. An oxygen generator, consisting of two tanks crammed with a sieve, supplies a degree of 93 percent oxygen to each piece of equipment that uses it. The oxygen generator generates oxygen using the Pressure Swing Adsorption (PSA) technique. During this process, the oxygen within the air is separated from the opposite elements.

Although the excellence between a concentrator and a generator is usually misunderstood, it's important to contemplate these characteristics in a very veterinary clinic. A concentrator may be a portable medical gadget that's less costly to use reception than a generator. However, a concentrator can not be utilized in a very veterinary clinic since it's not powerful enough to produce the equipment with the required level of oxygen. As hostile a concentrator, a generator generates 90 PSI, enabling you to run the flush on your anesthetic machine.

Another advantage is that the generator's reservoir can still supply you with oxygen in the event of an influence failure (the size of the reservoir varies with the various models). Nevertheless, in the event of an emergency or protracted equipment failure, we advise keeping an oxygen tank readily available.

Using pulse-dose flow regulators will help your oxygen cylinder work more efficiently. because the patient inhales, the machine briefly releases oxygen. They waste oxygen after they exhale in this way. The machine still has to be founded to the continual flow regulator's required LPM. Nowadays, a good range of economic and industrial manufacturing processes use oxygen generators. These devices are required for the generation of the requisite quantities of oxygen gas to power various operations. A zeolite molecular sieve frame and two columns surround the PSA Oxygen Generator. Gas enters the active column after rising through the zeolite.

How Medkav Technology Is Helping?

Media might be the ideal option for an oxygen generator because our products offer a cutting-edge design with many modules connected in parallel and include molecular sieves or zeolites. Each module is autonomous; if one stops working because of a filter issue, the others will still work with a simple pipe+cable connection. There are many diverse applications for this module. The newly created adsorber, which uses mechanical pre-tightening technology, effectively reduces friction between molecular sieves, which results in reduced molecular sieve pulverization, a longer sieve life, and higher purity levels.

We have a continuous relationship that is suited to our customers' current and future needs. We deliver excellent service (USP) We provide prompt and attentive service, a team of experts with a variety of strengths to help our clients resolve various types of service issues at reasonable prices, and a dedicated single point of the contact account manager to service each client, in contrast to the majority of other businesses (current market alternatives/competitors).