Medical oxygen generators operate according to the Pressure Swing Adsorption (PSA) theory. This traditional method of gas separation is employed to separate oxygen from compressed air. Two adsorbent containers, a surge tank, switching valves, an intelligent PLC, an oxygen analyzer, and several instruments make up the main parts. Due to its bigger molecular structure and ability to pass past the Adsorber to the surge tank, Zeolite does not preferentially adsorb Oxygen; instead, it preferentially adsorbs Nitrogen and CO2.

But in PSA Oxygen generators generations have passed. Medkav technologies provide 4th generation oxygen generators which are more user-friendly and highly advantageous than others. The first-generation oxygen generators use only a single tank (2 tanks containing zeolites), and no backup of Zeolites in case of breakdown. If any problem with Molecular sieves in any of the two tanks, then the whole plant will STOP. The first-generation plants are very complex to use and have High temp. in Iron tank and due to internal rubbing in molecular sieves causes ATTRITION (Powdering) of Molecular sieves, hence less life of Molecular sieves and Purity level problem exists. In addition to this in first-generation oxygen generators, Manual Tampering or settings can be done to increase or decrease any parameter. Continue reading to know which is the Best 4th Generation Oxygen Plant In India.

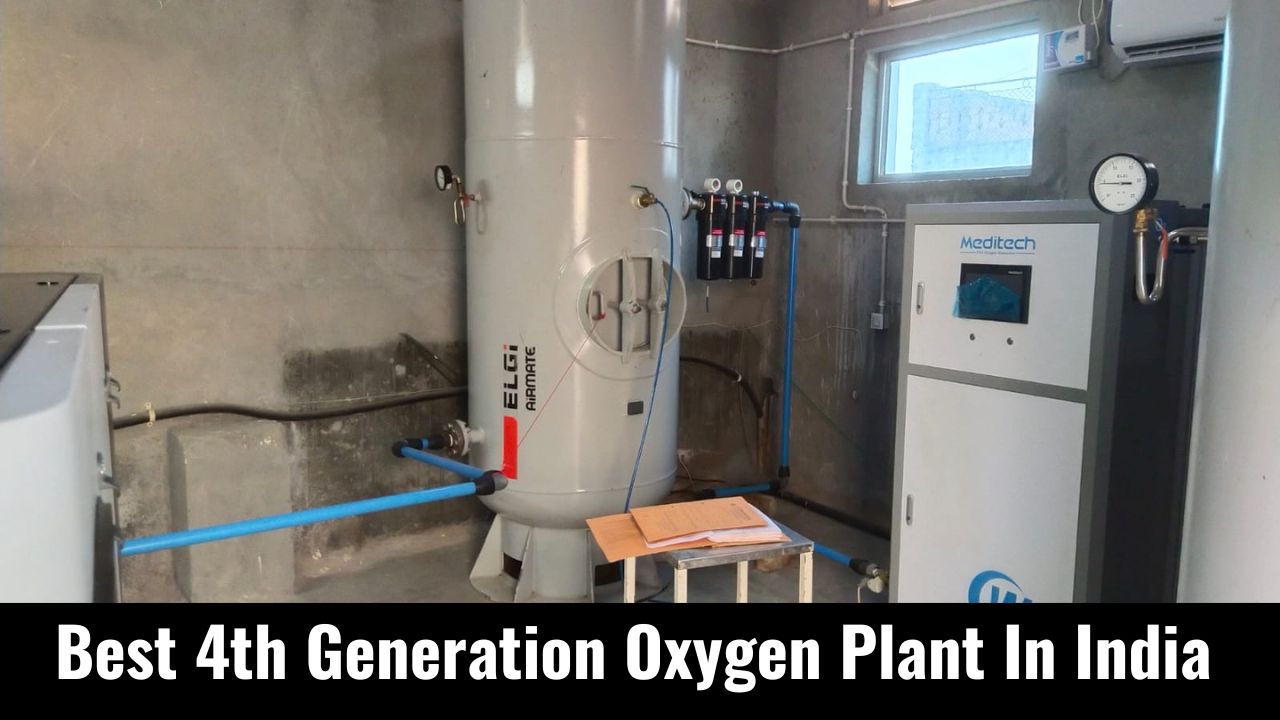

Best 4th Generation Oxygen Plant In India

A new Oxygen Generator with multiple Modules parallel connected contains Molecular sieves or Zeolites.

The interaction between the electrostatic field of the cationic zeolite and the quadrupole moments of the nitrogen and oxygen causes zeolite adsorbents to adsorb nitrogen as opposed to oxygen selectively. Since nitrogen has a quadrupole that is three times greater than that of oxygen, it selectively binds to the surface of zeolites. Zeolite 13X has exceptional nitrogen to oxygen adsorption selectivity, making it the most popular commercial zeolite for oxygen concentration processes.

Zeolite molecular sieves for oxygen generators are available in two primary types: sodium type and lithium type. In comparison to sodium-type zeolite molecular sieves, lithium-type zeolite molecular sieves are more effective at reducing the volume of oxygen generators, making them more compact and user-friendly.

While in the case of 1st generator Oxygen generator plant, Only a single - single tank was used(2 tanks containing zeolites), no backup of Zeolites in case of breakdown.

Each module can work Independently, If any Module breaks down due to failure of filters the rest keep WORKING.

Each module in the 4th generation oxygen generator plant works independently. This basically means that every module will work independently, and no module is connected or dependent on each other. That's why if any one or two of your modules breaks down or fails to work, the entire module or entire system will continue to work. This type of generator is much better for your business as you will not have to spend money on system failure every time a single module stops working. The others will continue to function.

Other Benefits of Medkav's 4th generation Oxygen Generators

- 1. compact pipe+cable connection and flexible module arrangement.

- 2. The Adsorber of the Oxygen Generating Module has been carefully created to reduce the molecular sieve tunneling effect and improve oxygen generation efficiency.

- 3. By utilizing Mechanical Pre-tightening Technology, which lessens the pulverisation of molecular sieves, the newly designed Adsorber efficiently avoids rubbing between molecular sieves.

Why Medkav 4th Generation Oxygen Generators Are Better Than Others?

- 1. compact pipe+cable connection and flexible module arrangement.

- 2. The Adsorber of the Oxygen Generating Module has been carefully created to reduce the molecular sieve tunneling effect and improve oxygen generation efficiency.

- 3. By utilizing Mechanical Pre-tightening Technology, which lessens the pulverisation of molecular sieves, the newly designed Adsorber efficiently avoids rubbing between molecular sieves.

- 1. Production of oxygen on-site has no supply chain risk.

- 2. Safety: There are no longer any explosion or fire risks associated with filling cryogenic tanks or storing high-pressure cylinders.

- 3. Consistent Purity: PSA's oxygen purity is 93 percent + 3 percent, which is in compliance with US Pharmacopeia standards.

- 4. Huge Savings: 65–70% reduction in current oxygen consumption

- 5. System built for continuous use for 24 hours a day, 7 days a week.

- 6. Autonomy: Make only what you need

- 7. Less Operating Cost: Break-even point is reached within 6 to 3 years.

- 8. Compact System: Requires less room. Installable on a terrace, a room, or a hallway