In order to create a plan for averting the catastrophe and being ready for future demands, it is crucial to think back on the circumstances that severely restricted our O2 supply. When the Covid-19 crisis hit India suddenly and most affected patients required LMO care, there was a severe liquid medical oxygen (LMO) shortage. Oxygen cylinder requests inundated social media. The commercial sector, NGOs, and government agencies sprang into action right away to set up LMO for the traumatized victims.

Whether we talk about LMO Plants or Oxygen generators, both are very necessary for medical sectors. Does this mean both the activities are the same? Well, I wouldn't agree with this as both end results might be a little the same, but they are totally different from each other. In order to feed the gas into industrial operations in real-time or store it in pressure tanks, oxygen generators separate oxygen from the air. Numerous industrial uses, including aquaculture, life support, and gold mine, use oxygen generators.

Today's industrial manufacturing is heavily dependent on high-purity oxygen for a variety of uses. Having access to a specialized oxygen generator makes obtaining the necessary quantities of oxygen gas more affordable.

So, let's dig into what actually is the difference between LMO Plants And Oxygen Generators.

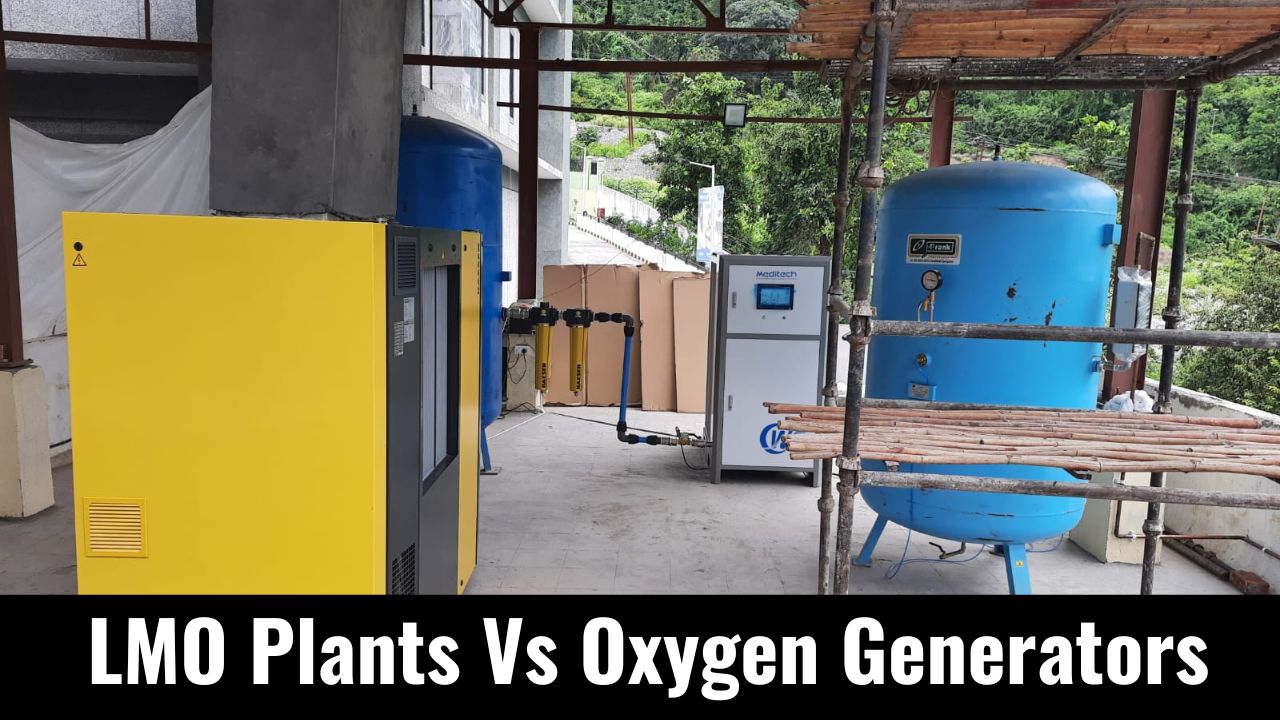

LMO Plants Vs Oxygen Generators

Definition

Oxygen Generator: An oxygen generator is a device that uses pressure swing adsorption, a unique selective adsorptive technique, to separate oxygen from compressed air (PSA). With 21% oxygen and 78% nitrogen, compressed air utilized in the oxygen generation process has a comparable chemical make-up to the outside air. Compressed air's oxygen is permitted to pass through a molecular sieve made of zeolite, which traps nitrogen and produces high purity oxygen at gas production outlets.

Argon and CO2 are two further trace gases that are present in normal ambient air together with 78 percent nitrogen and 21 percent oxygen. An oxygen generator is used to eliminate nitrogen and trace gases.

LMO Plant: Medical oxygen that has been liquefied by being cooled to its boiling point of -183 degrees Celsius is known as LMO. Transporting, storing, and breathing the liquid form is simpler than the gas form.

Medical oxygen is a colorless, odorless liquid that only solidifies at temperatures between -190 and -183 degrees Celsius. The liquid will transform back into its gaseous molecular state when kept at ambient temperature. The typical packaging for this product is PET bottles, plastic cylinders, or glass jars.

The most used type of medicinal oxygen is concentrated oxygen. It is available in higher amounts than ambient air, which contains 21% oxygen. It's also known as 40 volume or 40 percent at times.

Working Principle

Oxygen Generators: The technology used the most frequently to produce oxygen on an industrial scale is pressure swing adsorption (PSA). Inside a pressure tank containing Zeolite, PSA generators separate nitrogen from ambient air. A "molecular sieve," or zeolite, is a mineral that can be created naturally or artificially. Zeolite is helpful because of its capacity to "sort" molecules according to size. While the tiny oxygen molecules drift by and are gathered, the bigger nitrogen molecules are absorbed by the filter material. The tank is then pressurized once more once the pressure has been released and the nitrogen molecules have been vented to the atmosphere.

Gas will be 90–95% oxygenated after using PSA. Repeating the procedure allows for further improvement until more than 99 percent "pure" oxygen is produced.

LMO Plant: There are various techniques. The most popular method of manufacturing is the air separation unit, or ASU, which separates oxygen from other gases. Asus are essentially factories that separate huge quantities of gases. With 78 percent nitrogen, 21 percent oxygen, and the remaining 1 percent made up of various gases like argon, carbon dioxide, neon, helium, and hydrogen, they employ a process called fractional distillation to create pure oxygen from atmospheric air.

This approach involves chilling gases from the air into a liquid state, separating them into different components, and then extracting liquid oxygen from each component. First, atmospheric air is chilled to -181°C. Now, oxygen starts to liquefy. Since nitrogen's boiling point is -196°C, it can only exist as a gas. However, since argon has a boiling point that is comparable to that of oxygen (-186°C), a sizeable amount of argon liquefies with oxygen.

A second low-pressure distillation vessel is used to further purify the resulting mixture of oxygen and argon before it is drained, decompressed, and passed through. The final product is obtained as liquid oxygen that has been thoroughly purified, and it is then delivered in cryogenic containers.

What Else To Know About Oxygen Generators?

While industrial oxygen generators can fill a room, the smallest oxygen generators are no bigger than a Coke can. However, the goal of every oxygen generator is to deliver a steady stream of concentrated oxygen gas.

Companies that require large quantities of oxygen gas frequently begin by buying tanks of the gas from other businesses, who then fill those tanks using an industrial oxygen generator. If they have a significant and recurring requirement for pure oxygen, it might be more affordable to buy their own oxygen generator equipment and generate oxygen on-site. Despite the high initial cost of the equipment, it can eventually pay for itself because the cost per cubic foot of oxygen created is about 1/3 to 1/2 that of buying bulk oxygen.

What Else To Know About LMO Plant?

Large bulk cryogenic liquid oxygen tanks that are periodically replenished by a truck from a supplier may be installed in healthcare facilities. With no reliance on an external power source, the liquid oxygen tank powers the hospital's centrally-piped system (MGPS). Health Liquid MGPS is required for oxygen (LMO). a location on a hospital campus that is secure, open, and unrestricted. Additionally, it requires the building of a storage tank, which calls for a PESO license and outside supply dependency. A minimum of one to two days' worth of oxygen must also be kept on hand as a recommended practice. as a fallback, cylinders (Reserve). It is much more efficient, cost-effective, and secure to use liquid oxygen than Supply can be made by PSA plants or cylinders, however, both options depend on the provider.