We are aware that oxygen makes up 65% of the human body. Yes, oxygen is necessary for respiration, which is the process through which cells receive energy from glucose. In actuality, oxygen is needed by every cell in our body. When we breathe in air, oxygen atoms travel to our lungs, where they pass through the lung tissue and into our blood.

The use of liquid medical oxygen is one method of supplying this oxygen (LMO). LMO is simply high purity oxygen that is created for usage in the human body and is utilized for medical therapy. At room temperature, oxygen is in a gaseous state due to its low melting and boiling temperatures. Larger volume storage and simpler transportation are made possible by liquification.

- (1) Administration of Liquid Medical Oxygen (LMO) is free of operational expenses. Once the valve is opened, the medical gas flows automatically into the hospital's Medical Gas Pipeline System (MGPS) after being filled into the tank on hospital property. There is no need for additional labor, electricity, or upkeep.

- (2) According to IP 2018, the oxygen purity from this source is 99 percent v/v. Additionally, the purity is continuous and is unaffected by flow, etc. This makes it perfect for use in critical ICU beds and with ventilators.

- (3) LMO has a considerable amount of storage space. Approximately 870 liters of gaseous oxygen are included in one liter of liquid medical oxygen.

- (4) LMO has no flow rate restrictions. Simply put, it provides at whatever flow rate the hospital needs at any given time. If the flow required by the hospital at any particular time exceeds the flow rating of the oxygen source, other oxygen sources could fail or shut down.

How LMO Generator Produces Oxygen?

LMO can be created using a variety of techniques. The most popular production technique uses air separation units to separate oxygen (ASUs).

The many gases that make up atmospheric air are divided into discrete components using the fractional distillation method after being cooled into a liquid form. Then, liquid oxygen is drawn out of it.

MUST-READ ||

Why Is An LMO Installation Required To Be Registered With The Controller Of Explosives In India?

"First, the atmosphere is cooled to -181 degrees celsius. At this point, oxygen becomes liquid. Since nitrogen has a boiling point of -196 degrees Celsius, it is always in a gaseous state. However, because Argon's boiling point (-186 degrees Celsius) is similar to that of oxygen, a sizable amount of Argon liquifies with oxygen "

In order to separate the two gases, the resulting combination of oxygen and argon is drained, decompressed, and passed through a second low-pressure distillation tank. Ultimately, cryogenic containers are used to obtain purified liquid oxygen.

What Are Cryogenic Containers?

The creation and behavior of materials at very low temperatures are known as cryogenics. The definition of a cryogenic liquid is a liquid with a normal boiling point lower than -90°C.

For the safe and efficient transportation and storage of liquefied gases at cryogenic temperatures lower than -90°C, cryogenic liquid containers have been specifically created. Liquid gases are kept in these well-insulated containers at extremely low temperatures.

Things You Should Know About A LMO Generator Plant

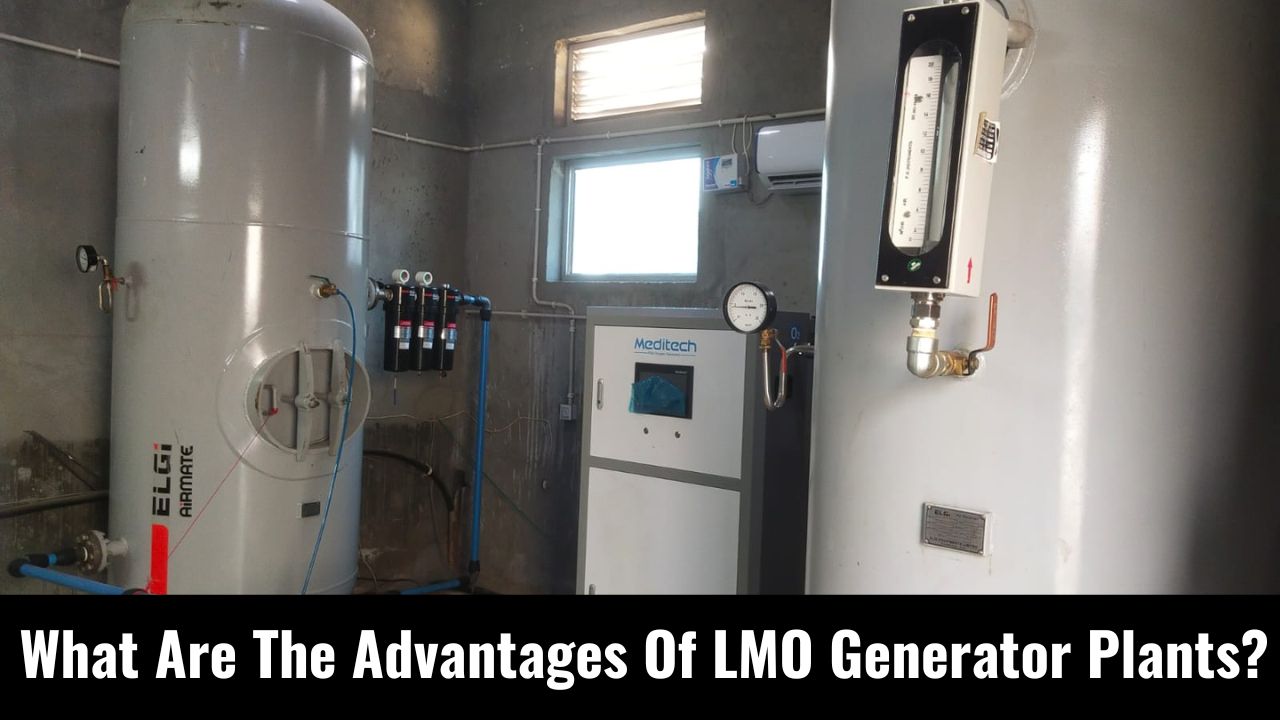

The boiling point of cryogenic liquids, which are liquefied gases, ranges from -150 to -270 degrees Celsius. At -183 degrees Celsius, liquid oxygen is present in a cryogenic state. A cryogenic storage tank, vaporizers, and pressure control system make up a conventional liquid oxygen storage system.

Depending on how much the user needs, many types of containers are used to store, transport, and handle liquid oxygen. The Dewar, cryogenic liquid cylinder, and cryogenic storage tanks are some of the container types in use. All tanks have circuits to control product fill, pressure buildup, pressure relief, product withdrawal, and tank vacuum. They are also vacuum insulated.

The liquid oxygen is changed into a gaseous state via vaporizers. The gas pressure provided to the process or application is then managed by a pressure control manifold. The atmospheric vaporizer needs to be made of a non-ferrous material that is suited for low-pressure operation.